We seek the broadest and most global use of Internet of Things to monitor equipment, work tools and security elements among others that allow, on the one hand, the exploitation of data with the aim of improving physical security both in real time and in subsequent analytics and, on the other hand, to improve efficiency in electrical system management.

To improve network development and asset management efficiency

Active

Development of a real-time interface able to reliably identify the open/closed/intermediate status of the disconnector and to deliver all the disconnector data to a VR platform, allowing the technician have an overview of the status and minimise the visual inspection time of the disconnector, reducing costs and man-hours of this activity.

Objective: To achieve predictive maintenance of the disconnector, controlling all its variables, minimising and even eliminating the local operating costs associated with disconnector operations.

Validation of the developed system in a real environment.

To improve network development and asset management efficiency

Active

Solution benchmark (2) and service models for submarine cable sensing via optical fibre. Calibration and characterisation tests will be performed in a real environment and then a benchmarking period of approximately 2-3 weeks will be initiated with each solution.

Validation of a submarine cable monitoring system capable of detecting and classifying the main potentially hazardous events for the cable.

To improve the sustainability of our processes and activities

Active

Elewit is working on a project that consists, on the one hand, in the implementation of a sensor that identifies the presence of sulphur hexafluoride and quantifies its concentration in ppm in the high voltage compartment isolated with SF6 gas, while, on the other hand, it is also developing and validating the electronics necessary to adapt the signal obtained from the sensor to a quantifiable measurement in engineering units, as well as the communications circuits to facilitate its transmission and thus improve predictive maintenance.

This proposed use case essentially takes advantage of the multi-connective and ultra-reliable nature associated with 5G technology. The tests are run in the the Morvedre sub-station, close to Sagunto.

• Development of a sensor that identifies the presence of sulphur dioxide.

• Development and validation of the electronics necessary to adapt the signal obtained from the sensor to a quantifiable measurement in engineering units.

• Installation of the sensor in a switch at the Morvedre substation.

Improve network development and asset management efficiency

Active

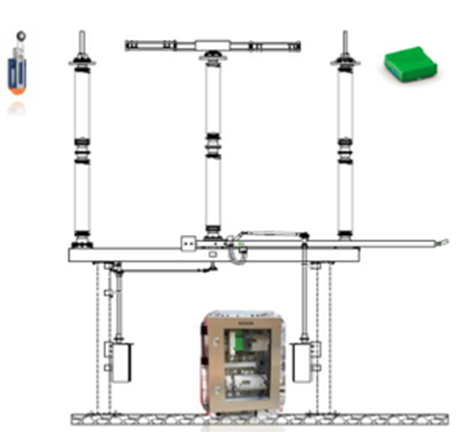

In this project, low-cost IoT devices that are minimally invasive are developed, in order to monitor the dynamic response of safety elements and detect unsafe behaviours when carrying out work on transmission grid elements.

Design and manufacturing of prototype(s)

Validation of prototype(s) in transmission grid elements

Validation of the MVP in transmission grid elements

Industrialisation and integration to third parties